product

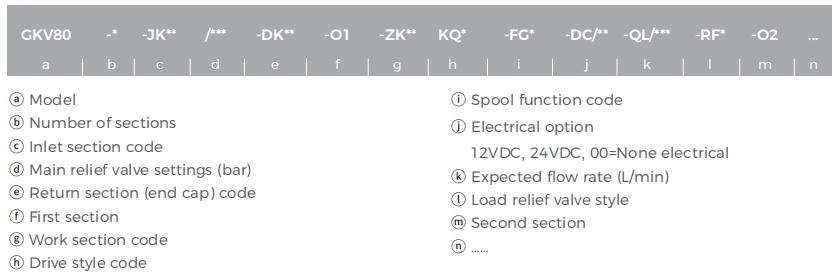

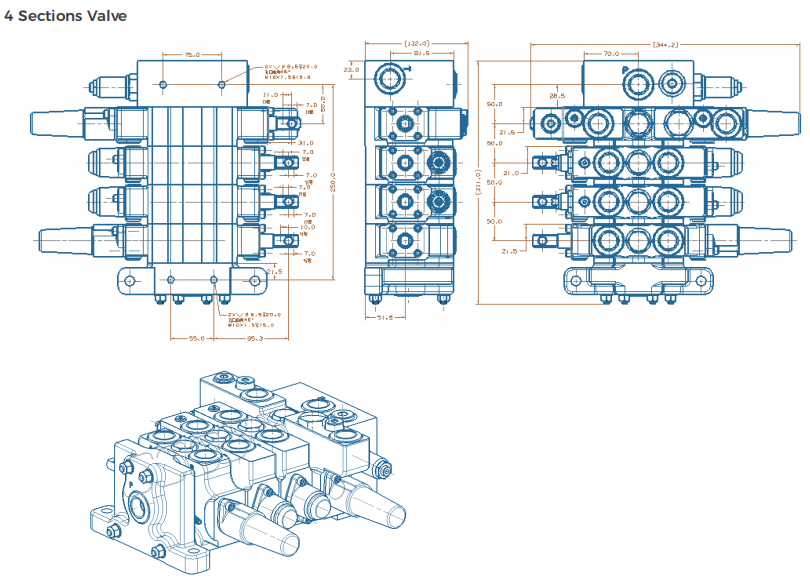

GRH has 3 series of different sectional valve for different applications, GKV35, GKV50 and GKV80. The multi-way valve of the GKV series is a modular open multi-way valve, modules with different functions can be selected to meet the design of various complex systems.

GKV80 series sectional valves are open circuit valves. Mainly used in mobile machines such as agricultural machinery,construction machines, mining equipment, material handling equipment as well as maintenance machines. All valve series adapt modular design. The system designer can choose different modules to design a complex system. Main valve spool is designed to satisfy with the customer requirements, which provides excellent flow characteristics an very low flow force. With different inlet modules, it gives user the freedom for choosing different relief valve and different port locations. There are numbers of different work section modules to choose to satisfy the customer needs. Different end sections also provide the customer needs for return ports or power beyond functions.

| Rated Flow Rate | 80L/min | Max. Pressure at T port | 25bar |

| Max. Flow Rate | 100L/min | Internal leakage(@70 bar)A, B to T | <8cc/min |

| Min. Flow Rate | 20L/min | With P.O. check | <3cc/min |

| Max. Pressure at P port | 350bar | Spool stroke(1, 2 position) | +7/-7mm |

| Max. Pressure at A, B port | 350bar | With floating function(1, 2 and F position) | +7/-7 -10mm |

| Solenoid can be either 12 or 24VDC, corresponding current is 0-1.5 or 0-0.75 Amp. | |||

RYAN GKV80 series load sensing proportional valves are widely used in crane trunk,tractor,loader, forklift and harvester.